charpy impact testing lab|charpy impact testing methods : convenience store The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is . Resultado da Folhetos mais recentes. Dê uma olhada no encarte com as atuais ofertas da loja Assaí Atacadista em Rio de Janeiro - Av. Padre Guilherme .

{plog:ftitle_list}

web3 dias atrás · Goth Galore. Your eyes didn’t deceive you! The goth hoodie in this Kit will no longer enlarge the eyes of your female Sims while worn. Not to worry; the change in eye .

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically .Supported by our ISO 17025-accredited testing laboratories, Element’s Charpy impact test services deliver precise test results with competitive turnaround times, helping you align with international standards.Charpy Impact Test - Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Impact testing machine Standard charpy specimens (also called as ‘notch’ specimens) Furnace and thermocouple (to heat the specimen and increase its temperature) Liquid nitrogen (to lower the temperature of the specimen) Tongs (to hold and .As an independent, accredited mechanical test lab, Charpy Impact Testing is conducted at ATRONA on a daily basis per ASTM A370/E23. ATRONA has two high capacity pendulum impact testers and employs state of the art sample preparation and testing methods. Part size does not matter. Hardness of the part does not matter either.

Charpy Impact Test. To find the impact resistance of mild steel. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] . Follow Us. AGPL 3.0 .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Charpy Impact Testing Lab Standards. The Charpy V-notch impact tests are performed to common international standards such as ASTM E23. Reliable Results: Our team comprises PhDs, engineers, chemists, metallurgists, and technicians, all dedicated to delivering fast and precise results. Clients can trust the reliability of Titan Metallurgy’s .

charpy impact testing procedure

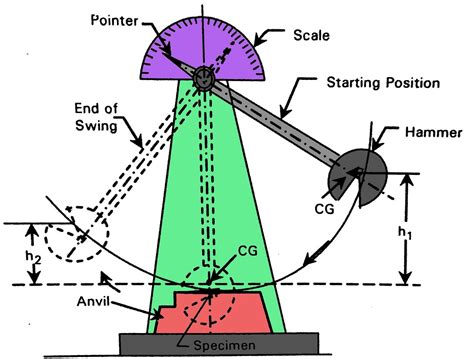

Laboratory Testing Inc.’s (LTI) Impact Testing Lab, located near Philadelphia, offers metal impact testing using the drop weight test and Charpy impact testing methods, including the Charpy V-notch test and the weld Charpy test. We can conduct testing at temperatures of -452ºF to 500ºF with an impact energy of up to 320 ft. lbs.specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.Drop-Weight and Charpy V-Notch Tests. Examining the Charpy Effect Metals’ impact resistance or toughness can be measured by subjecting them to impact testing, which involves measuring the amount of energy absorbed by the material before it breaks. To determine if the impact energy is affected by temperature, the test is carried out at a range of temperatures.

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different temperature -78°C, 80°C and 7°C respectively were utilized.Laboratory Testing Inc.’s (LTI) Impact Testing Lab, located near Philadelphia, offers metal impact testing using the drop weight test and Charpy impact testing methods, including the Charpy V-notch test and the weld Charpy test. We can conduct testing at temperatures of -452ºF to 500ºF with an impact energy of up to 320 ft. lbs.

test scenarios for white paper

charpy impact testing lab report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides instructions for conducting a Charpy impact test to investigate how the energy absorbed during deformation and fracture of metals varies with temperature. Students will perform Charpy tests on copper alloy and aluminum alloy . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .The ATS Marietta Super Lab, which performs all Charpy impact testing, is an ISO 9001:2015 registered entity. Our certification shows that a qualified third-party auditor found our quality management system to be compliant with the internationally recognized standards outlining effective quality assurance practices. ATS takes this extra step to . Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural .

Download Charpy impact test report and more Advanced Machining Processes Lab Reports in PDF only on Docsity! Experiment No. 2 Charpy Impact Test Shiva Yadav Aerospace Engineering, 3rd Sem (Dated: August 10, 2022) This report is a summary of the experiment to determine the Toughness of materials known as the Charpy Impact Testing .Cite this chapter. Subhash, G., Ridgeway, S. (2018). Charpy Impact Testing. In: Mechanics of Materials Laboratory Course.Charpy and Izod Impact Testing The Charpy or the Izod impact test is carried out by testers using a pendulum impact testing apparatus. A device having a swinging pendulum that is released to strike a secured specimen is referred to as a pendulum impact testing machine or a pendulum impact tester. A weighted hammer on [.]

During the ASTM E23 Charpy impact testing procedure, our technicians strike a bar-shaped specimen with a hammer that is attached to a pendulum. Technicians measure the force needed to break the specimen which provides important insight into .

the impact test, the energy absorbed in foot-pound, ft and the energy converted to the International System of Units. Table 4. Impact Energy Absorbed for AISI 1045 Low Temperature Water Bath. Specime n Temperature, T, oC Measured Impact Energy, EIM, ft Converted Impact Energy SI, ESI, J. 1 3 21 28. 2 1 24 32. 3 2 22 30. Average 2 22 30. LAB 2: CHARPY IMPACT TEST 1 1. Introduction The impact test is a high-strain rate assessment of the material properties where a hammer attached to an arm will drop in a pendulum motion and impact the test specimen. The critical part of this experiment is the samples which will be prefabricated into the Charpy V-notch design which is a 55x10x10 mm .The mechanical properties of materials are ascertained by performing carefully designed laboratory experiments that replicate, as nearly as practical, the service conditions. Factors to be considered include . (ksi), and CVN is the standard Charpy V-Notch impact test value. 3 Figure 1(a) and 1 (b) – Schematic Drawing of a Standard Impact .Impact Testers. Model IT 30 Charpy Impact Tester as per ASTM standard. Model IT 30 Charpy / Izod Impact Tester (ASTM E 23) Laboratory Facility. Complete workshop facilities including Lathe Machines, CNC wire cut machine, Hacksaw, Stress-free grinding

Mechanical Testing – Metals. Tensile testing (-40°F to +2000°F) Crack tip opening displacement (CTOD) testing; Charpy V-Notch Impact Testing; Nick-break and bend testing; Proof load, pull testing; Burst testing; Stress rupture testing; Hardness testing; Weld and Braze Evaluation and Qualification; Coating Inspection & TestingTo determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

charpy impact testing methods

testing interview questions white paper

testing interview questions why the paper is white

WEBIn-Play. Casino. Live Casino. Offers. Betslip. Mega Roulette. Already have a BetVictor Canada account? Log in to your account for all your favourite betting markets and Casino games.

charpy impact testing lab|charpy impact testing methods